The customer’s cutting discs cannot move?

The customer’s cutting discs cannot move?

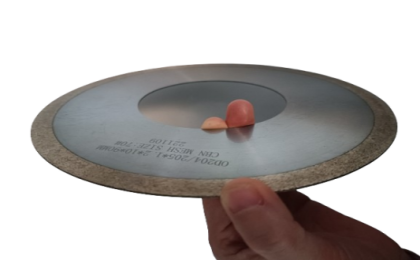

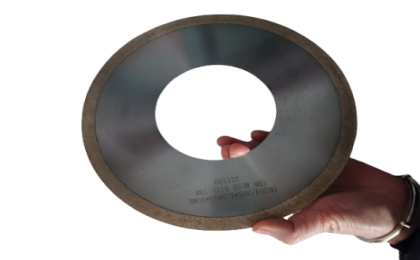

CBN metal bond cutting discs for processing high-speed steel rolling cutters.

The customer feedback is that it is a bit difficult to grind, with a feed rate of 0.8-1 thread. If there is more, there will be smoke and it cannot be ground in.

In general, there are several reasons why the cutting discs cannot move:

1. Improper selection of cutting discs abrasive

2. Inappropriate hardness of cutting discs

3. Issue with feed rate

4. cutting discs wear or blockage

5. Material issue of workpiece

6. Cutting heat effect

7. Cutting discs installation and transmission issues

8. Coolant issue

In summary, to address the issue of cutting discs not being able to move, we need to conduct a comprehensive analysis and solution from the aspects of cutting discs abrasive selection, cutting discs hardness, feed rate, cutting discs wear and dressing, workpiece material, cutting heat, cutting discs installation and transmission, and coolant.

By selecting and adjusting these factors reasonably, we can effectively improve the cutting effect of the cutting discs, ensuring the improvement of workpiece processing quality and production efficiency.

Solution:

1. CBN metal bond CBN metal bond cutting discs are generally hard, and the cutting discs formula is softened.

2. Make the grain size as coarse as possible to improve efficiency, confirm with the customer whether the roughness of the rolling cutter is qualified, and then see if adjustments are needed.

Finally,JINCHENG can not only make according to client drawing size, but also according to client special grinding situation,such as the hardness and shape of the CBN metal bond cutting discs required by the end user.Then clients will make sure that JINCHENG formulation is really suitable for end users.JINCHENG provides customers with perfect after-sales service.