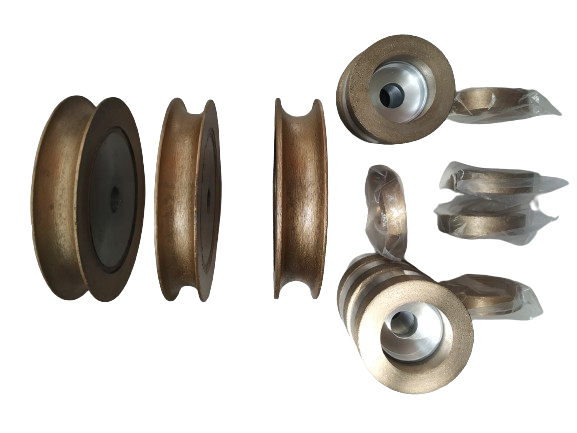

Metal bonded diamond grinding wheels with special shapes are usually customized according to specific processing needs to meet the processing requirements of complex workpieces.

Metal Bond Diamond Grinding Wheel is a superhard material tool that uses metal powders (such as copper, iron, cobalt, nickel, etc.) as binders to fix diamond abrasive particles on a substrate through high-temperature sintering. This type of grinding wheel has the characteristics of high strength, high wear resistance, high service life, and excellent thermal conductivity, and is particularly suitable for processing difficult to machine materials such as hard alloys, ceramics, and glass.

Special shaped metal bonded diamond grinding wheels are widely used in aerospace, automotive manufacturing, electronic information, optical instruments and other fields, especially in the processing of high-precision and high hardness parts. For example, in machining processes such as aircraft engine blades, automotive crankshafts, and semiconductor chip cutting, these types of grinding wheels play an important role.

1. Raw material preparation

Select high-quality diamond abrasive grains and metal powders as raw materials.

2. Mixed pressing

Mix diamond abrasive particles and metal powder in a certain proportion and press them into shape.

3. Sintering treatment

Sintering treatment is carried out on the formed body under high temperature conditions, so that the metal powder melts and wraps around the diamond abrasive particles to form a strong bonding layer.

4. Processing and trimming

Necessary processing and trimming of the sintered grinding wheel to meet usage requirements.

1. Customized design

Metal bonded diamond grinding wheels with special shapes are usually customized according to specific processing needs to meet the processing requirements of complex workpieces. The shapes of these grinding wheels may include various curves, grooves, slopes, etc. to ensure machining accuracy and surface quality.

2. High precision machining

Due to the high hardness and sharpness of diamond abrasive grains, as well as the good retention of metal binders, this type of grinding wheel can achieve high-precision machining, ensuring the dimensional and shape accuracy of the workpiece.

3. Efficient grinding

Metal bonded diamond grinding wheels have high grinding efficiency and material removal rate, and can complete a large number of processing tasks in a short period of time, improving production efficiency.

4. Long lifespan

Due to the high wear resistance of diamond abrasive grains and the stability of metal binders, the service life of such grinding wheels is usually longer, reducing the number of wheel replacements and downtime.

Metal bond diamond grinding wheel is a cutting tool that uses diamond as the cutting material, which is widely used in the processing of hard and brittle materials such as glass, concrete, refractory materials, stone, ceramics, etc.

1A1 OD350MM Metal Bond Diamond Grinding Wheel is a type of grinding wheel that uses metal binders (such as bronze, nickel, etc.) to firmly bond diamond abrasive grains together.

Metal bond diamond grinding wheels play an important role in precision machining of ceramic materials due to their high strength, high wear resistance, and good thermal conductivity.

If you need our products please write down any questions, we will reply as soon as possible.