Semiconductor Industry

With the rapid development of technology, the semiconductor industry, as the core and foundation of information technology, is increasingly becoming an important force driving global economic progress. In this field, high-precision machining tools are one of the key factors in ensuring the quality and performance of semiconductor products.Jincheng grinding wheels have excellent performance and stable quality, and are widely used in the semiconductor industry.

![]()

![]()

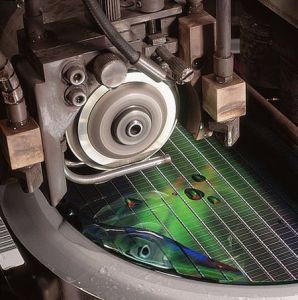

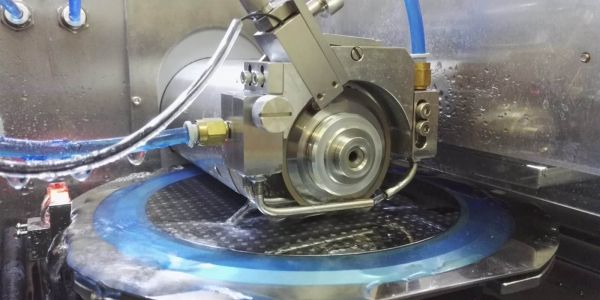

1. Silicon wafer cutting and grinding: In the semiconductor manufacturing process, the cutting and grinding of silicon wafers are crucial steps. Grinding wheels can ensure the flatness and smoothness of silicon wafer surfaces to extremely high standards through precise grinding control, laying a solid foundation for subsequent processing procedures.

![]()

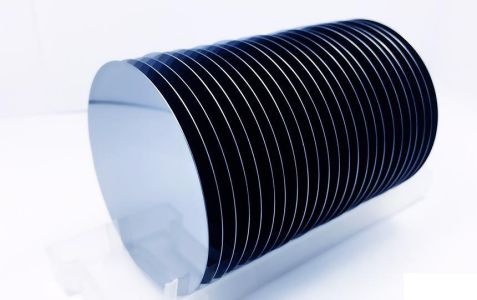

2. Wafer thinning and polishing: With the continuous development of semiconductor technology, the size of wafers is gradually increasing, and the requirements for thinning and polishing processes are also becoming higher and higher. Using grinding wheels for wafer thinning and polishing can significantly reduce the thickness and surface roughness of the wafer, improve the heat dissipation performance and integration of the chip.

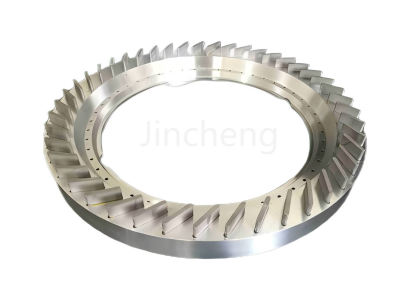

3. Precision cutting and slicing: In the semiconductor packaging process, precision cutting and slicing are indispensable steps.Jincheng grinding wheel can be installed on precision cutting machines.Using grinding wheels for cutting and slicing can ensure that the flatness and accuracy of chip edges meet extremely high standards, improving packaging yield and product quality.

Advantages of Jincheng Grinding Wheel in the Semiconductor Industry:

1. Jincheng grinding wheel uses high-quality diamond as abrasive, which has extremely high hardness and wear resistance, and can easily cope with the hard and brittle characteristics of semiconductor materials, achieving efficient and precise grinding processing.

2. The selection and proportioning of Jincheng grinding wheel binder have been carefully designed to ensure that the grinding wheel has good stability and self sharpening during use, effectively extending its service life and improving processing efficiency.

3. We can also provide customized production services based on the drawings you provide.

4. Jincheng’s reduction grinding wheels can be used for wafer thinning and polishing, ensuring the flatness of the wafer surface, reducing defects, and improving the performance of the final product.