JINCHENG Sapphire grinding wheels with stable quality

Substrate sapphire wafer process

From the sapphire ingot to the final substrate sapphire sheet, it mainly includes the following steps: crystal growth → rod extraction → head and tail truncation → rolling grinding → crystal rod orientation → slicing → chamfering and edging → rough and fine grinding → CMP polishing. Each step needs to be equipped with different diamond tools to complete, the main tools are drill bits, grinding wheels, wire saws and so on.

Crystal growth: use a crystal growth furnace to grow large-sized and high-quality single-crystal sapphire crystals;

Pull out the rod: use the sapphire drill bit (high-precision nesting drill bit) to pull out the sapphire crystal rod from the sapphire crystal;

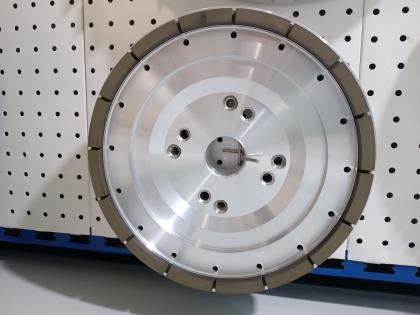

Roll grinding: use diamond grinding wheel (resin bond or metal bond) to carry out flat grinding of the crystallization direction and outer diameter grinding of the ingot to obtain accurate outer circle size accuracy; ( Now rough grinding is generally metal grinding wheel, fine grinding is Ceramic grinding wheel, there are also resin grinding wheels for coarse and fine grinding in enterprises)

Orientation: Accurately locate the position of the sapphire crystal rod on the slicer, which is convenient for precise slicing processing;

Slicing: Slicing the sapphire ingot into thin wafers using a diamond wire saw;

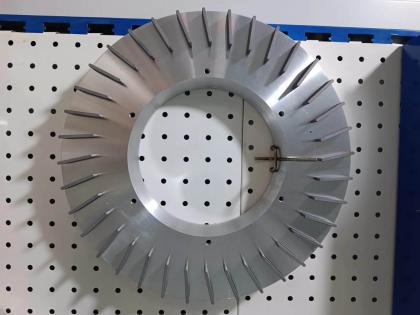

Chamfering and edging: the edge of the wafer is trimmed into an arc shape by using a metal bonded diamond grinding wheel to improve the mechanical strength of the edge of the sheet;

Grinding: remove the wafer cutting damage layer caused by slicing and improve the flatness of the wafer. It is divided into rough grinding and fine grinding, and the abrasive products involved mainly include diamond grinding discs, diamond grinding liquid, diamond back thinning grinding wheels, etc.;

Polishing: To improve the roughness of the wafer so that the surface reaches epitaxial wafer epitaxy-level precision, more CMP polishing fluid is used.

Packaging process

The epitaxy and packaging process mainly includes the following steps: substrate → epitaxial wafer → evaporation etching → heat treatment → backside thinning → grinding and polishing → scribing test → die bonding → wire bonding packaging → cutting → testing. The main abrasive products involved are diamond ultra-thin scribing knife, diamond back thinning grinding wheel, grinding liquid, polishing liquid, etc.