How the glass grinding wheels work on a glass bilateral machine?

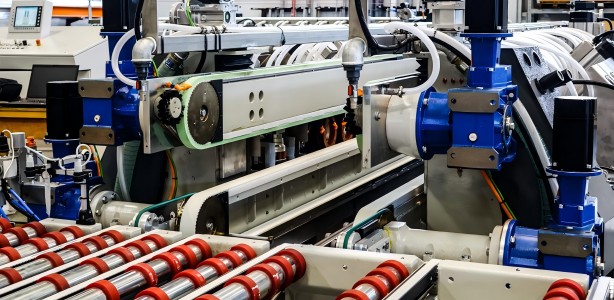

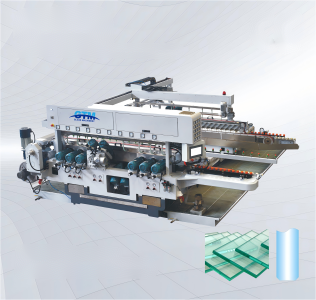

Bilateral machine, also known as bilateral glass edging machine, is an efficient glass processing equipment that can simultaneously grind, polish and other treatments on both sides of glass.

The working principle of the glass grinding wheel in the glass edging machine on the double-sided machine mainly involves the following aspects:

1. Start and Rotation

When the bilateral machine is started, the motor drives the spindle to rotate through the transmission device, which in turn drives the grinding wheel to rotate at high speed. The speed of the grinding wheel is usually adjusted according to the processing requirements and material properties.

2. Contact and Grinding

The rotating grinding wheel comes into contact with both sides of the glass, and the glass surface is ground by the abrasive particles on the grinding wheel. During this process, the contact pressure between the grinding wheel and the glass, as well as the rotational speed of the grinding wheel, jointly determine the efficiency and effectiveness of grinding.

3. Bilateral simultaneous processing

The biggest feature of the bilateral machine is that it can process both sides of the glass simultaneously, which greatly improves production efficiency. During the processing, the grinding wheel will grind the glass along the set trajectory until it reaches the desired shape and size.

4. Edge changing processing

As glass generally requires four sided grinding, after processing both sides of the glass, it will be transferred to a changing table to rotate the glass to the unprocessed sides for further processing.

5. Cooling and lubrication

In order to prevent overheating and rapid wear of grinding wheels and glass during processing, double-sided machines are usually equipped with cooling systems. The cooling system cools and lubricates the grinding wheel and glass by spraying coolant to extend the service life of the grinding wheel and improve processing quality.

6. After being ground by bilateral machines

The edges of the glass become smooth, flat, and meet specific shape requirements.As needed, the processed glass may require subsequent processing steps such as polishing, cleaning, and drying to further improve its surface quality and appearance.

Our Jincheng Abrasives is currently promoting glass grinding wheels specifically designed for double-sided machines.The diamond grinding wheel produced by Jincheng for grinding glass has the advantages of high hardness, high grinding efficiency, long service life, high safety, and strong applicability.If you need,please contact us!