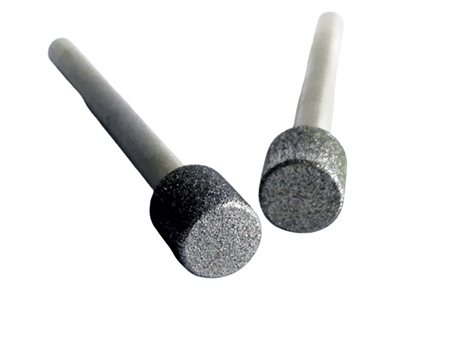

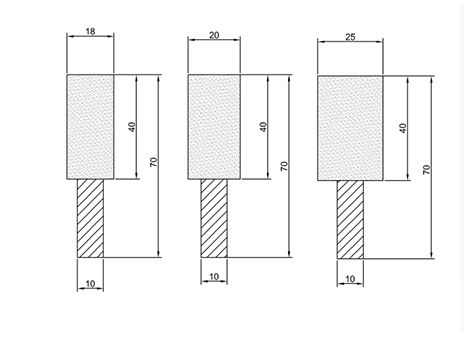

Electroplated CBN Diamond Grinding Pins is a precision internal grinding tool that combines electroplating technology, cubic boron nitride (CBN), and diamond characteristics.

1. Material properties

CBN and diamond are one of the hardest materials known, known as "superhard abrasives". They have extremely high hardness, wear resistance, compressive strength, and good thermal conductivity, which makes them perform well in grinding and cutting processes.

2. Manufacturing process

CBN or diamond particles are firmly attached to the metal substrate through electroplating process, forming a grinding tool with high precision and durability.

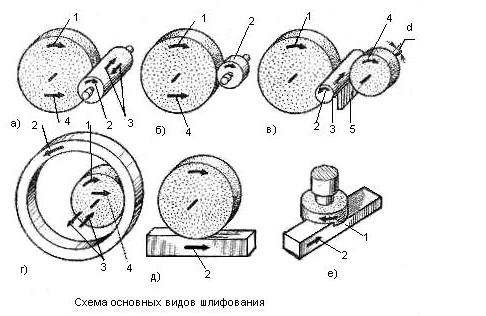

1. Mechanical processing

Used for grinding and polishing high-precision parts, such as automobile engine crankshafts, camshafts, gear shafts, etc.

2. Tool manufacturing

Used for fine grinding and finishing in the manufacturing process of tools such as cutting tools and molds.

3. Material processing

In the field of materials science, it is used to process various difficult to process materials such as ceramics, graphite, etc.

1. High precision

Due to the extremely high hardness of CBN and diamond, these grinding needles can maintain precise size and shape during the machining process, ensuring the accuracy of the processed workpiece.

2. High wear resistance

The high wear resistance of CBN and diamond allows these grinding needles to maintain sharp cutting edges even after long-term use, reducing replacement frequency and improving production efficiency.

3. Wide applicability

Suitable for grinding various difficult to machine materials, such as high-speed steel, hard alloys, ceramics, etc. Especially when processing black metals, CBN grinding wheels have greater advantages compared to diamond grinding wheels.

4. Cold cutting capability

CBN and diamond have good thermal conductivity, which can quickly dissipate grinding heat, reduce workpiece thermal deformation, and are suitable for grinding materials with low thermal conductivity.

5. Economy

Due to the high durability of CBN and diamond, these grinding needles have a long service life and a long dressing cycle, reducing the frequency of replacement and dressing and lowering production costs

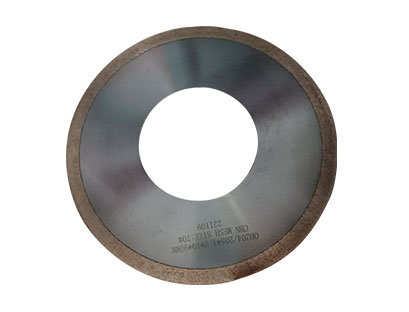

Metal bonded diamond grinding wheels with special shapes are usually customized according to specific processing needs to meet the processing requirements of complex workpieces.

Cubic Boron Nitride (CBN) metal bond diamond grinding wheel is a high-performance grinding tool widely used in the processing of various high hardness materials.

The Diamond Metal Bond Grinding Wheel is a high-performance, high-precision grinding tool that excels in grinding difficult to machine materials due to its unique combination of diamond abrasive particles and metal bonding agents.

If you need our products please write down any questions, we will reply as soon as possible.