Glass Edge Grinding Problem and Solution

The following problems often occur during glass processing: uneven chamfering, uneven grinding, edge breakage, corner breakage, indentation, scratches, etc. Below, Jincheng will analyze the reasons and solutions for these problems.

1. Glass edging has lines and burnt edges

Reason 1: The glass transmission speed is too fast.

Solution: The transmission speed of the edging machine conveyor belt can be adjusted according to the thickness of the glass, instead of blindly pursuing fast speed.

Reason 2: The grinding ratio configuration of the grinding wheel is unreasonable, and the grain size of the first grinding wheel is too coarse, making it difficult for the subsequent grinding wheels to smooth out the patterns left by the first grinding wheel.

Solution: You can adjust the particle size ratio of the grinding wheel, choose the appropriate grinding wheel, and install a professional scar removal and precision grinding wheel, which can efficiently solve the problem of grain patterns.

Reason 3: The cooling water pipe is blocked, not aligned with the grinding point, or the cooling water is insufficient, resulting in insufficient water pressure and inability to cool the grinding wheel.

Solution: Remove debris and glass dust from the water pump, water distribution pipe, and grinding wheel water pipe.

2. White scratches or shiny ripples appear on the edges of the glass

Reason: The reason for the appearance of white scratches is that one of the polishing wheels has low pressure; The reason for the appearance of shiny ripples is due to excessive pressure on the polishing wheel. If the material of the polishing wheel is hard, the probability of this phenomenon occurring is high.

Solution: Adjust the pressure of the polishing wheel; And use elastic polishing wheels. Generally speaking, good polishing wheels have relatively good elasticity and are less sensitive to pressure.

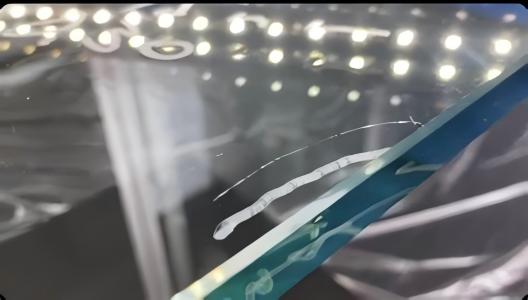

3. Laminated glass has irregular scratches

Reason: The reason for this situation may be due to the interlayer adhesive bonding on the grinding wheel.

Solution: Trim the grinding wheel and remove the interlayer adhesive.

4. Glass explosion edge

Reason 1: Excessive grinding amount.

Solution: Reduce the amount of grinding.

Reason 2: Too much margin at the edge of the glass or too fast conveying speed.

Solution: It is recommended to reduce the glass allowance by 1-2mm on one side, and adjust the conveying speed of the conveyor belt according to the glass thickness and polishing requirements.

Reason 3: Insufficient cooling water.

Solution: Check the cooling system, remove debris and glass dust from the water pump, water distribution pipe, and grinding wheel water pipe.

Reason 4: The angle of the grinding wheel is not correct or sharp.

Solution: Replace the grinding wheel or adjust the grinding wheel angle.

Choosing Jincheng Grinding Wheel not only provides customers with high-quality products, but also offers excellent services. Jincheng can provide customers with specialized problem solutions when using our products.