Jincheng full segmented diamond grinding wheel is the first position on glass edging machine,which is used for building glass,furniture glass,and other similar glass sheets rough grinding.Suit for straight line/double edging machine,beveling machine and so on.

Full segmented diamond wheels are specialized grinding tools designed for precision glass processing. They are particularly effective for edging and shaping glass with thicknesses ranging from 3mm to 25mm.

1. Glass Thickness

Suitable for various glass thicknesses, particularly effective for architectural and furniture glass.

2. Machinery Compatibility

Often used in edging machines and double edging machines, they are positioned as the primary grinding tool (position 1) for optimal results.

3. Efficiency

The design allows for improved feeding speed and reduced risk of burning the glass during the grinding process.

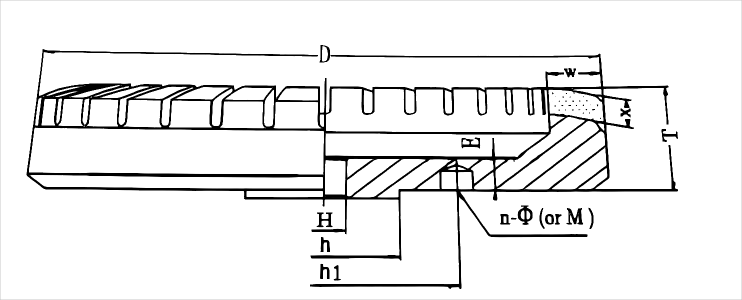

| Outer Diameter(mm) | Bore(mm) | Thickness(mm) | Rim width(mm) | Rim height(mm) | Grit(mm) |

| 150-175 | 12,22,50,70 | 38mm or customized | 10-15 | 8-10 | 80#,100# |

1. Segmented diamond grinding wheels have high hardness and wear resistance, as well as high grinding efficiency and long service life.

2. Segmented design helps reduce vibration and noise during the grinding process, improve grinding accuracy and surface quality.

3. Segmented design allows the heat generated during the grinding process to dissipate faster, avoiding thermal damage and deformation caused by overheating of the grinding wheel.

4.JINCHENG can not only make according to client drawing size, but also according to client special grinding situation,in order to make sure that JINCHENG formulation is really suitable for end users.

5. The regular standard size is available in JINCHENG stock, when you need them, we can send them to you within a couple of days.

These polishing wheels are used for last Position polishing on single edging machine,double edging machine,beveling machine,profile edging machine.

Suit straight edge machine,beveling machine,bilateral machine,numerical control machine,such as Bavelloni,Bottero,Glassline,Schiatti,etc Jincheng full rim diamond grinding wheel usually used on the position NO.2 or NO.3 according to the machine type.Which is suitable for all kinds of glass in glass-industry.

If you need our products please write down any questions, we will reply as soon as possible.