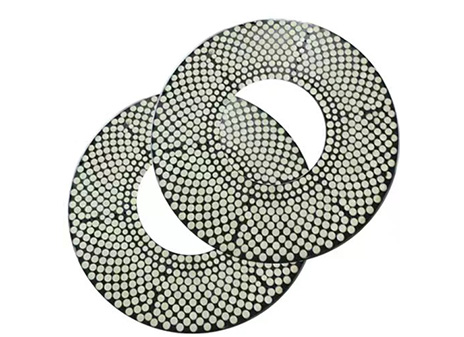

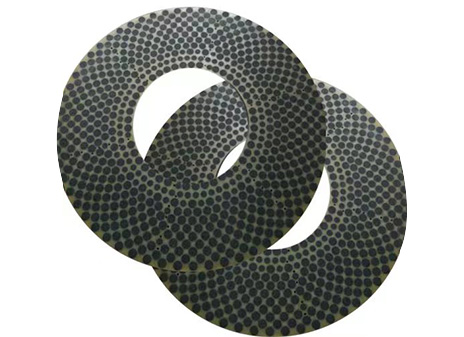

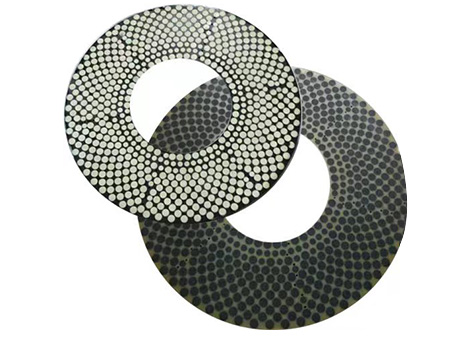

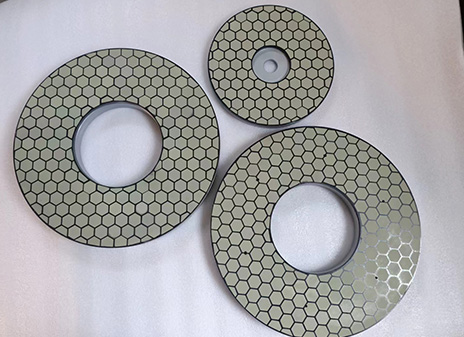

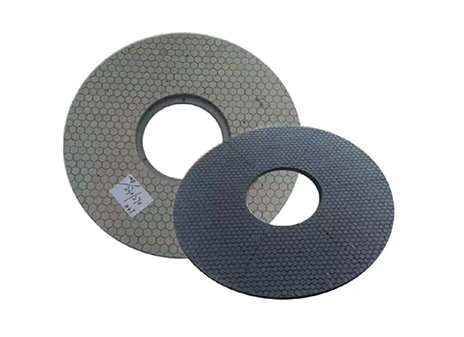

Vitrified bond diamond and CBN honing discs are used for fine grinding bearing end faces, piston rings, gaskets, shims, compressor parts, vane pump stators, rotors, vane end faces, semiconductor materials, magnetic materials, tools, precision springs, etc.

The vitrified bond diamond grinding wheel has high strength, good heat resistance, sharp cutting, high grinding efficiency, not easy to heat and block during the grinding process, and small thermal expansion to control the machining accuracy.

Compared with resin-bonded grinding wheels, it solves the problems of low life and low grinding efficiency and the changeability of the grinding wheel itself during the grinding process.

The above advantages of ceramic-bonded diamond grinding wheels have been widely used in wafers (semiconductor silicon wafers and solar silicon wafers), diamond composite wafers, diamond polycrystalline, diamond tools, cubic boron nitride, tungsten steel (hard It has achieved good economic benefits in the machining of high-hardness and brittle materials such as new engineering structural ceramics, precious stones, crystals, and rare earth materials (magnetic materials).

The vitrified bond diamond grinding wheel has high strength, good heat resistance, sharp cutting, high grinding efficiency, not easy to heat and block during the grinding process, and small thermal expansion to control the machining accuracy.

1. High grinding efficiency;

2. It has high wear resistance (the grinding wheel has high wear resistance and less consumption of abrasive grains, especially when grinding very hard and brittle workpieces);

3. Small grinding force and low grinding temperature;

4. The workpiece to be ground has high precision, good surface quality and good shape retention.

Therefore, the vitrified bond diamond grinding wheel has more and more advantages in the grinding of some special materials such as diamond, industrial ceramics, diamond composite sheet, diamond polycrystal, diamond tool, cubic boron nitride, hard alloy and other high-hard and brittle materials. It has obvious advantages and has a good prospect in the development of diamond abrasive tools. It is considered to be a high-performance abrasive tool with high speed, high efficiency, high precision, low grinding cost, and low environmental pollution. It has more and more applications and is a hot spot in the research and development of grinding tools in various countries in the world.

| Grinding wheel specification | The number of parts processed by each group of grinding wheels | Roughness | flatness | The dimensional error between |

| single disc parts | ||||

| Ф100~Ф1200mm | 500,000 to 1,500,000 pieces | Ra0.05μm to Ra0.2μm | ≤2μm | 1 to 2 μm |

If you need our products please write down any questions, we will reply as soon as possible.