The Diamond Metal Bond Grinding Wheel is a high-performance,high-precision grinding tool that excels in grinding difficult to machine materials due to its unique combination of diamond abrasive particles and metal bonding agents.

1. Main materials: diamond abrasive grains and metal binders. Diamond is known for its extremely high hardness and wear resistance, while metal binders provide excellent mechanical support and thermal conductivity.

2. Manufacturing process: Diamond abrasive particles are tightly bonded with metal powder through high-temperature sintering technology to form a grinding wheel with high strength and wear resistance.

1. Aerospace: Used for processing high-precision and high hardness parts such as aircraft engine blades and turbine disks.

2. Automobile manufacturing: Processing key components such as automobile crankshafts and camshafts.

3. Electronic information plays an important role in precision machining fields such as semiconductor chip cutting and ceramic substrate grinding.

4. Optical instruments: Processing high-precision optical components such as lenses, prisms, etc.

5. Stone and ceramic processing: suitable for cutting and grinding hard and brittle materials such as stone slabs and ceramic tiles.

1. High hardness and wear resistance

Diamond abrasive grains have extremely high hardness, allowing the grinding wheel to maintain a sharp cutting edge during the machining process. At the same time, the metal bonding agent also has good wear resistance, extending the service life of the grinding wheel.

2. Efficient cutting

The high sharpness of diamond abrasive grains enables the grinding wheel to achieve efficient cutting during the machining process, improving machining efficiency.

3. Good thermal conductivity

Metal binders have good thermal conductivity, which can dissipate the heat generated during the grinding process in a timely manner, avoiding overheating of the workpiece and burning of the grinding wheel.

4. Customized design

Diamond metal bond grinding wheels can be customized according to different processing needs, such as adjusting the concentration of abrasive particles, the type of bond, and the shape of the grinding wheel, to meet specific processing requirements

5. JINCHENG can not only make according to client drawing size, but also according to client special grinding situation,such as the hardness and shape of the ceramic grinding wheel required by the end user.Then clients will make sure that JINCHENG formulation is really suitable for end users.

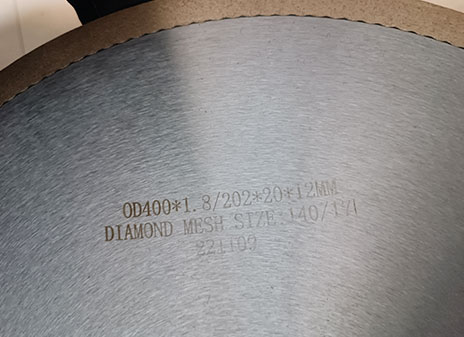

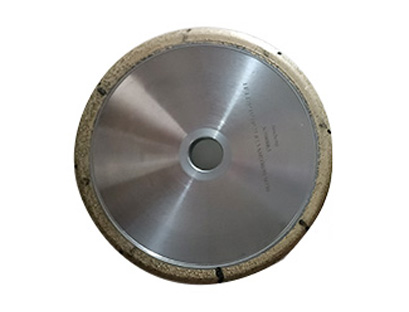

1F1 OD175MM metal bond diamond grinding wheels are a superhard material tool that uses metal powder as a binder to fix diamond abrasive particles on a substrate through high-temperature sintering.

1A1 OD350MM Metal Bond Diamond Grinding Wheel is a type of grinding wheel that uses metal binders (such as bronze, nickel, etc.) to firmly bond diamond abrasive grains together.

Metal bond diamond grinding wheels play an important role in precision machining of ceramic materials due to their high strength, high wear resistance, and good thermal conductivity.

If you need our products please write down any questions, we will reply as soon as possible.