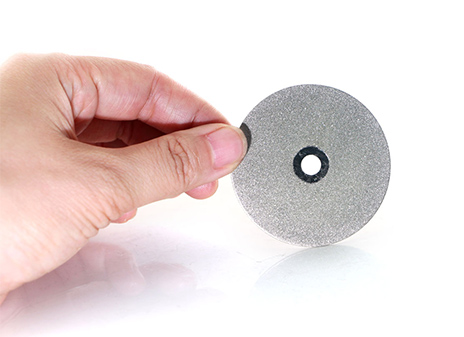

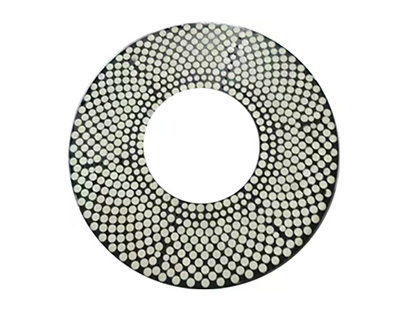

Electroplated Diamond Cutting Discs are cutting tools that use electroplating technology to fix diamond particles onto a metal substrate.

Electroplated diamond cutting discs are used for the marble and granite edge grinding and sharpening with manual equipment.

OD 065 X T0.8mm D301

We can make the specification according to your drawing size.

1. Good diamond control

Electroplating technology forms a strong bond between diamond particles and the metal substrate, making it difficult for them to fall off prematurely, thus fully utilizing the cutting performance of diamond particles.

2. Suitable for manufacturing thin thickness discs

Electroplated diamond cutting discs are suitable for manufacturing thinner cutting discs and are suitable for fine cutting operations.

3. Small impact on substrate properties

The electroplating process causes minimal thermal damage to diamond particles, maintaining the original strength of diamond and fully utilizing its characteristics.

4. Simple production process and low cost

The production process of electroplated diamond cutting discs is relatively simple, with a short production cycle and low cost, suitable for large-scale production.

5. High cutting efficiency

Electroplated diamond cutting discs perform well during the cutting process and can efficiently complete cutting tasks.

Vitrified bond diamond and CBN honing discs are used for fine grinding bearing end faces, piston rings, gaskets, shims, compressor parts, vane pump stators, rotors, vane end faces, semiconductor materials, magnetic materials, tools, precision springs, etc.

The surface diamond grinding machine is used to process the two end faces of grinding wheel with diameter less than or equal to 500 mm and thickness less than or equal to 150 mm.

One Point Diamond Dresser is a high-precision tool used for dressing grinding wheels, grinding tools, or other grinding surfaces.

If you need our products please write down any questions, we will reply as soon as possible.