These polishing wheels are used for last Position polishing on single edging machine,double edging machine,beveling machine,profile edging machine.

Jincheng can customize polishing wheels of different specifications according to customer requirements.

1. CE3 Polishing wheels

Moderate hardness, delicate polishing effect, capable of producing high glossiness, and long service life. Mainly used for fine polishing of glass double-sided machines, especially suitable for occasions with high requirements for polishing effect.

2. X5000/X3000 Polishing Wheels

These cerium oxide polishing wheels are designed for fine polishing, especially effective on glass and metals. They are commonly used in industries such as automotive, aerospace, and electronics.

3. X7000 Polishing Wheels

Similar in function to the X3000 and X5000, this wheel is also tailored for high-quality polishing tasks.

4. X081 Polishing Wheels

In the field of glass processing, the X081 polishing wheel is used for precision polishing of equipment such as glass edge machines and double-sided grinders; In the field of metal manufacturing, the X081 polishing wheel is used for smoothing and enhancing the gloss of metal surfaces.

5. X098 Polishing Wheels

The X098 polishing wheel is designed specifically for the final polishing of glass edges, making it an essential tool in glass processing industries.

6. SD001 Polishing Wheels

SD001 polishing wheel may be a precision polishing grinding wheel designed specifically for glass edge grinders. It has high polishing accuracy and stability, and can produce uniform glossiness. Mainly used in the final polishing stage of glass edging machines to ensure the smoothness and aesthetics of glass edges.

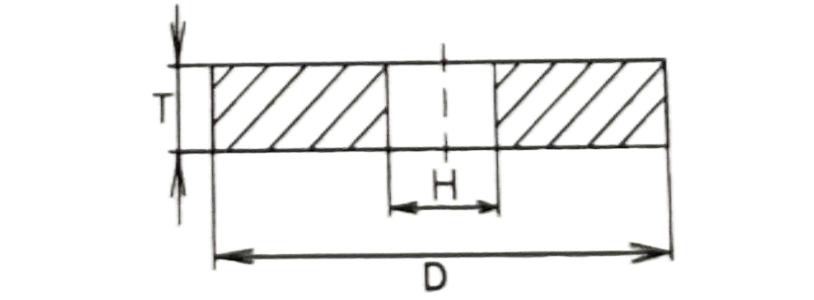

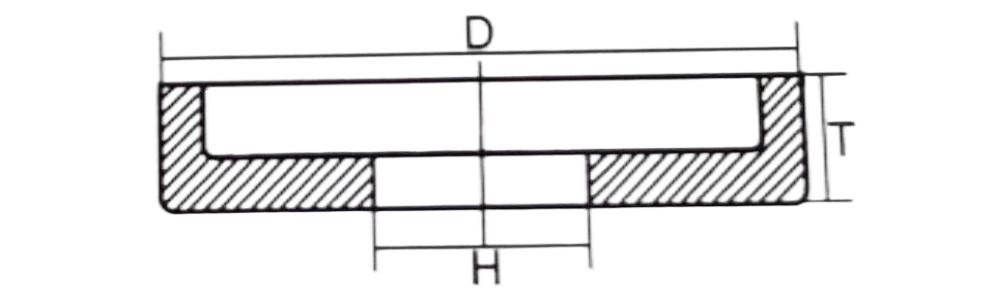

| Diameter(mm) | Thickness(mm) | Hole(mm) |

| 100、130、150、175 | 25、30、35、40 | 12、22、50、70、90 |

| 100、130、150、175、200 | 15、20、25、30 | 22、50、90 |

1. High-Quality Finish

These polishing wheels, particularly the cerium oxide variants (X3000, X5000, CE3), are designed to achieve a superior polished finish on glass surfaces. They enhance the transparency and clarity of the material, making them ideal for applications requiring aesthetic quality.

2. Durability and Efficiency

Constructed from high-quality materials, these polishing wheels exhibit excellent wear resistance and grinding speed.This durability ensures a longer lifespan and consistent performance over time, reducing the need for frequent replacements.

3. Customized production

Jincheng can customize production according to the drawings and parameters provided by customers, and provide professional services for customers.

Suit straight edge machine,beveling machine,bilateral machine,numerical control machine,such as Bavelloni,Bottero,Glassline,Schiatti,etc Jincheng full rim diamond grinding wheel usually used on the position NO.2 or NO.3 according to the machine type.Which is suitable for all kinds of glass in glass-industry.

Jincheng full segmented diamond grinding wheel is the first position on glass edging machine,which is used for building glass,furniture glass,and other similar glass sheets rough grinding. Suit for straight line/double edging machine,beveling machine and so on.

If you need our products please write down any questions, we will reply as soon as possible.