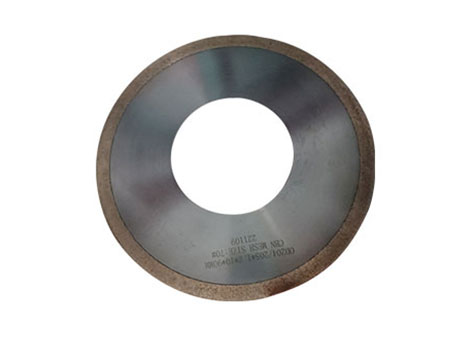

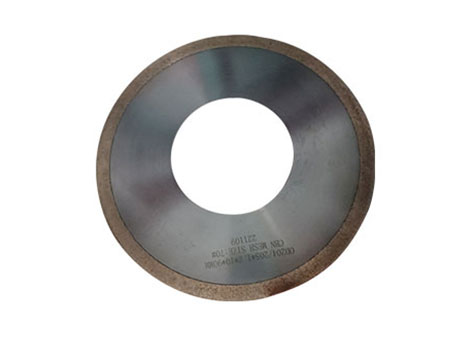

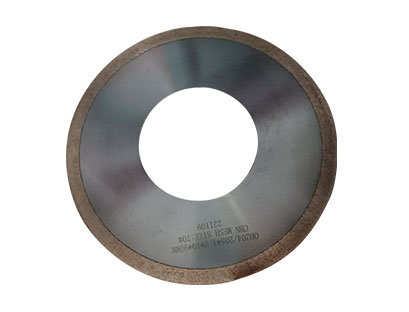

Cubic Boron Nitride (CBN) metal bond diamond grinding wheel is a high-performance grinding tool widely used in the processing of various high hardness materials.

CBN Metal Bond Diamond Grinding Wheels combine the excellent performance of CBN abrasives with the strong support of metal binders, providing an efficient and stable solution for precision machining. CBN, as a superhard material second only to diamond, has extremely high hardness and wear resistance, while metal bonding agents can ensure that the grinding wheel maintains stable shape and accuracy during use.

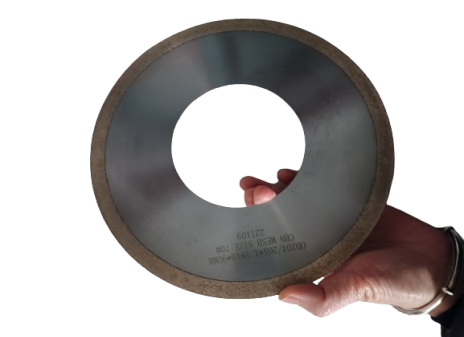

1. High hardness and wear resistance

CBN abrasive has extremely high hardness and wear resistance, which can easily handle the processing of various high hardness materials, such as hard alloys, ceramics, high-speed steel, etc. The metal bonding agent further enhances the wear resistance of the grinding wheel and extends its service life.

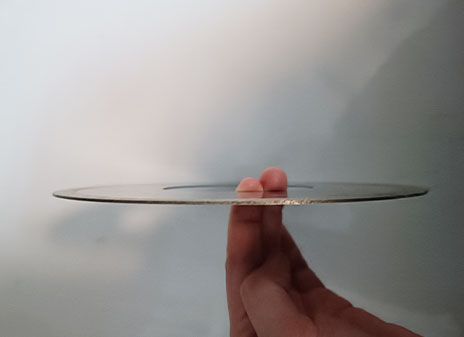

2. High precision and stability

CBN Metal Bond Diamond Grinding Wheels ensure high shape and dimensional accuracy through precise manufacturing processes and strict quality control. During use, the grinding wheel can maintain stable grinding performance and meet the requirements of precision machining.

3. Efficient grinding

The high hardness and sharpness of CBN enable the grinding wheel to quickly remove materials during the grinding process, improving machining efficiency. At the same time, the strong support of the metal bonding agent reduces vibration and deformation during the grinding process, further improving processing efficiency.

4. Wide applicability

This product is suitable for processing various high hardness materials and is widely used in various fields such as automotive, aerospace, mold manufacturing, electronics, optics, etc.

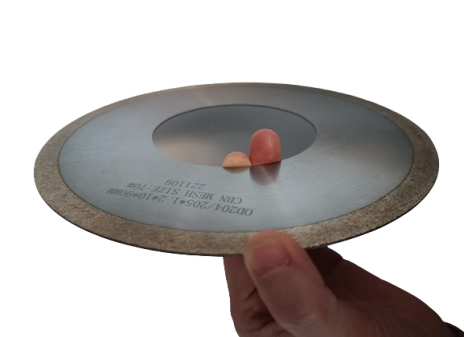

5. For the end users, these grinding wheels can not only save clients production costs, but also Improve working effiency.

6. JINCHENG can not only make according to client drawing size, but also according to client special grinding situation,such as end users ceramic grinding wheels hardness and shape.Clients will make sure that JINCHENG formulation is really suitable for end users.

7. The regular standard size is available in JINCHENG stock, when you need them, we can send them to you within a couple of days.

Roller Ring Metal Bond Diamond Grinding Wheel is a grinding tool designed specifically for high hardness and brittle materials.

Metal bonded diamond grinding wheel is a type of grinding wheel that uses metal bonding agents to fix diamond abrasive particles together.

If you need our products please write down any questions, we will reply as soon as possible.