Basic Knowledge Of Grinding Wheels

In the field of precision machining and grinding, diamond grinding wheels have become indispensable tools due to their excellent hardness and wear resistance. Understanding the grit size comparison table and common types of diamond grinding wheels is crucial for improving machining accuracy and efficiency.In addition, it is also necessary to understand the marking methods of diamond and CBN grinding wheels, which is of great help for better selecting suitable grinding wheels.Jincheng will provide you with basic knowledge of the grinding wheel industry, hoping to help you.

1. Comparison Table of Diamond Grinding Wheel Grit Size

The Grit Size of a Diamond Grinding Wheel refers to the size of abrasive particles on the wheel, which directly affects the efficiency of grinding and the quality of the machined surface.Regarding Diamond Grinding Wheel Grit Size, different countries have different standards.

|

China |

Internation |

western union |

America |

|||||

|

Grit |

Size(micron) |

GritⅠ |

GritⅡ |

Size(micron) |

Grit |

Size(micron) |

Grit |

Size(micron) |

|

16/18 |

1180/1000 |

1181 |

16/18 |

1180/1000 |

D1180 |

1180/1000 |

16/18 |

1180/1000 |

|

18/20 |

1000/850 |

1001 |

18/20 |

1000/850 |

D1001 |

1000/850 |

18/20 |

1000/850 |

|

20/25 |

850/710 |

851 |

— |

850/710 |

D851 |

850/710 |

20/30 |

850/600 |

|

25/30 |

710/600 |

711 |

— |

710/600 |

D711 |

710/600 |

|

|

|

30/35 |

600/500 |

601 |

— |

600/500 |

D601 |

600/500 |

30/40 |

600/425 |

|

35/40 |

500/425 |

501 |

— |

500/425 |

D501 |

500/425 |

|

|

|

40/45 |

425/355 |

426 |

— |

425/355 |

D425 |

425/355 |

40/50 |

425/300 |

|

45/50 |

355/300 |

356 |

— |

355/300 |

D356 |

355/300 |

|

|

|

50/60 |

300/250 |

301 |

50/60 |

300/250 |

D301 |

300/250 |

20/60 |

300/250 |

|

60/70 |

250/212 |

251 |

— |

250/212 |

D251 |

250/212 |

60/80 |

250/180 |

|

70/80 |

212/180 |

213 |

— |

212/180 |

D213 |

212/180 |

|

|

|

80/100 |

180/150 |

181 |

80/100 |

180/150 |

D181 |

180/150 |

80/100 |

180/150 |

|

100/120 |

150/125 |

151 |

100/120 |

150/15 |

D151 |

150/125 |

100/120 |

150/125 |

|

120/140 |

125/106 |

126 |

120/140 |

125/106 |

D126 |

125/106 |

120/140 |

125/106 |

|

140/170 |

106/90 |

107 |

140/170 |

106/90 |

D107 |

106/90 |

140/170 |

106/90 |

|

170/200 |

90/75 |

91 |

170/200 |

90/75 |

D91 |

90/75 |

170/200 |

90/75 |

|

200/230 |

75/63 |

76 |

200/230 |

75/63 |

D76 |

75/63 |

200/230 |

75/60 |

|

230/270 |

63/53 |

64 |

23/270 |

63/53 |

D64 |

63/53 |

23/270 |

63/53 |

|

270/325 |

53/45 |

54 |

270/325 |

53/45 |

D54 |

53/45 |

270/325 |

53/45 |

|

325/400 |

45/38 |

46 |

328/400 |

45/38 |

D46 |

45/38 |

325/400 |

45/38 |

|

Japan |

west germany |

Russia |

|||

|

Grit |

Size(micron) |

Grit |

Size(micron) |

Grit |

Size(micron) |

|

16/18 |

1180/1000 |

D1180 |

1180/1000 |

2500/2000 |

2500/2000 |

|

18/20 |

1000/850 |

D1001 |

1000/850 |

2000/1600 |

2000/1600 |

|

20/30 |

850/600 |

D851 |

850/710 |

1600/1250 |

1600/1250 |

|

|

|

D700 |

710/600 |

1250/1000 |

1250/1000 |

|

30/40 |

600/425 |

D601 |

600/500 |

1000/800 |

1000/800 |

|

|

|

D501 |

500/425 |

800/630 |

800/630 |

|

40/50 |

425/300 |

D426 |

425/355 |

630/500 |

630/500 |

|

|

|

D356 |

355/350 |

500/400 |

500/400 |

|

50/60 |

300/250 |

D301 |

300/350 |

400/315 |

400/315 |

|

60/80 |

250/180 |

D251 |

250/212 |

215/250 |

315/250 |

|

|

|

D213 |

212/180 |

250/200 |

250/200 |

|

80/100 |

180/150 |

D181 |

180/150 |

2001/160 |

2001/160 |

|

100/120 |

150/125 |

D151 |

150/125 |

160/125 |

160/125 |

|

120/140 |

125/106 |

D126 |

125/106 |

125/100 |

125/100 |

|

140/170 |

106/90 |

D107 |

106/90 |

100/80 |

100/80 |

|

170/200 |

90/75 |

D91 |

70/75 |

80/63 |

80/63 |

|

200/230 |

75/63 |

D76 |

75/63 |

63/50 |

63/50 |

|

230/270 |

63/53 |

D64 |

63/53 |

50/40 |

50/40 |

|

270/325 |

53/45 |

D54 |

53/45 |

|

|

|

325/400 |

45/38 |

D46 |

45/38 |

|

|

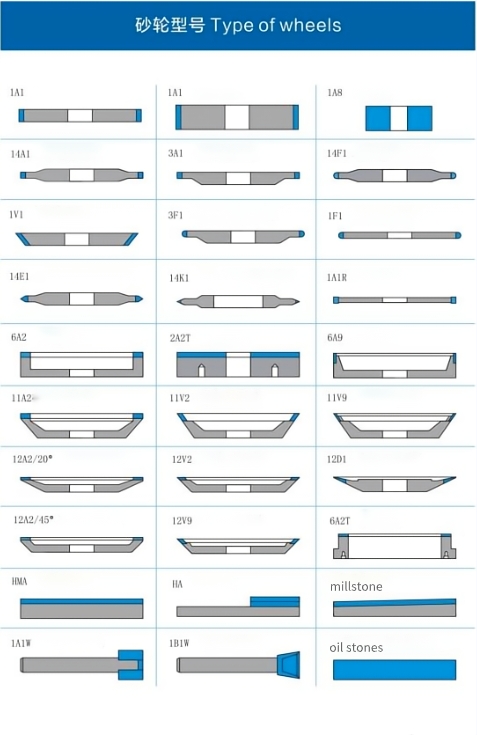

There are various models of diamond grinding wheels to choose from based on their shape and purpose.Here are some common types of grinding wheels.

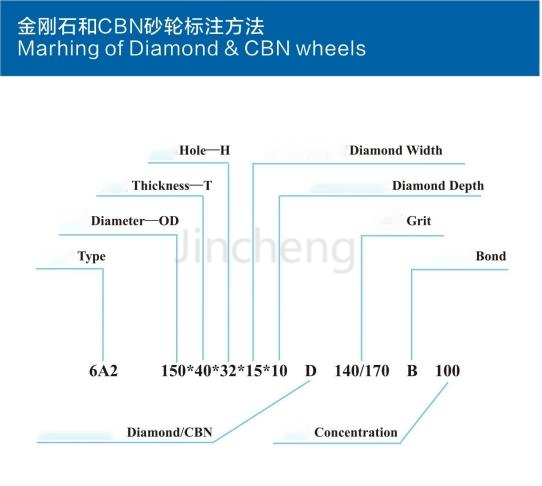

3. The marking methods of diamond and CBN grinding wheels

4. When ordering a grinding wheel, please be sure to provide us with the following information: the model, size, (outer diameter, thickness, aperture, abrasive layer width and thickness), abrasive, particle size, type and concentration of binder, grinding material, grinding parameters, etc. The more detailed and clear the description, the more suitable the grinding wheel can be obtained. Then Jincheng will provide customized production for you.