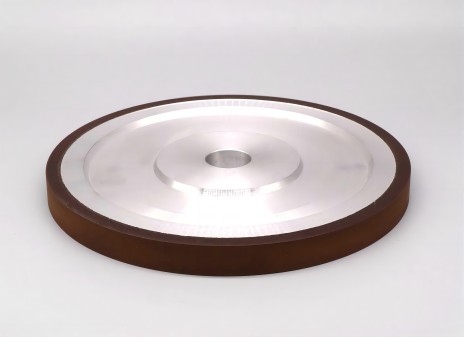

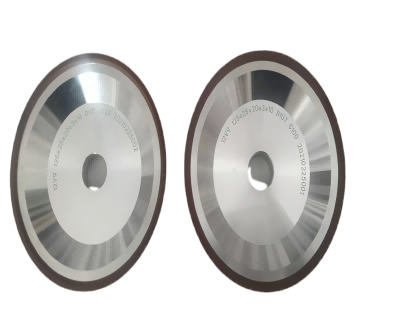

9A1 Resin Bond Parallel Grinding Wheels is a parallel grinding wheel product that uses resin as a bonding agent.

9A1 Resin Bond Parallel Grinding Wheel is commonly used in fields such as metal processing and tool manufacturing, and is particularly suitable for grinding operations that require high precision and parallelism.

1. In the field of metal processing, 9A1 Resin Bond Parallel Grinding Wheels can be used for grinding precision workpieces such as cutting tools and molds.

2.In the tool manufacturing industry, this grinding wheel can be used to manufacture high-precision and high-quality cutting tools.

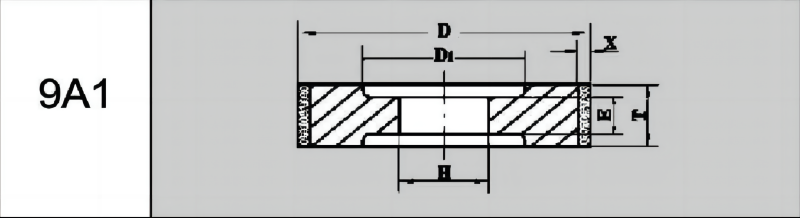

| D | T | H | X |

| 160MM | 25 | 16 | 2.5 |

| 170MM | |||

| 180MM | |||

| 190MM |

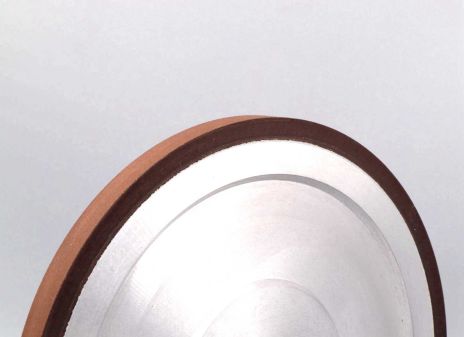

1. Efficient grinding

Resin binders have good self sharpening properties, which can maintain high sharpness during the grinding process and improve grinding efficiency.

2. Shape preservation

Parallel grinding wheels have good shape stability, which can ensure a constant shape and size during the grinding process and improve machining accuracy.

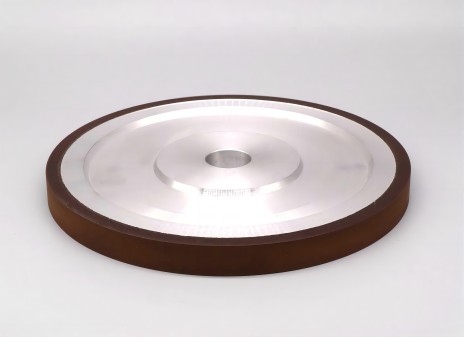

3. Long lifespan

High quality materials and manufacturing processes make this grinding wheel highly durable, which can extend its service life and reduce usage costs.

4. Wide applicability

It can be used to process various materials, including but not limited to iron-based alloys, non-ferrous alloys, etc.

5. JINCHENG can not only make according to client drawing size, but also according to client special grinding situation,such as the hardness and shape of the ceramic grinding wheel required by the end user.Then clients will make sure that JINCHENG formulation is really suitable for end users.

6. The regular standard size is available in JINCHENG stock, when you need them, we can send them to you within a couple of days.

Resin bonded diamond inner grinding wheel is a type of diamond tool mainly used for precision grinding and processing of various hard and brittle materials.

Resin bonded centerless grinding wheel is a type of grinding wheel made using resin as a bonding agent through a specific process for centerless grinding.The centerless grinding wheels usually instelled on the following grinding machines: Koyo, Crystec, Dedtru, Landis , Okuma, Paragon, Royal Master, Unison, WMV and so on.

12V9 Resin Bond Diamond Grinding Wheels are diamond grinding wheels that use resin as a bonding agent.

If you need our products please write down any questions, we will reply as soon as possible.