The 6A2 Metal Bond Diamond Grinding Wheel is a tool designed specifically for high-precision grinding and machining, widely used in various fields such as metal processing, tool manufacturing, aerospace, and more.

The 6A2 Metal Bond Diamond Grinding Wheel is a tool designed specifically for high-precision grinding and machining, widely used in various fields such as metal processing, tool manufacturing, aerospace, and more.

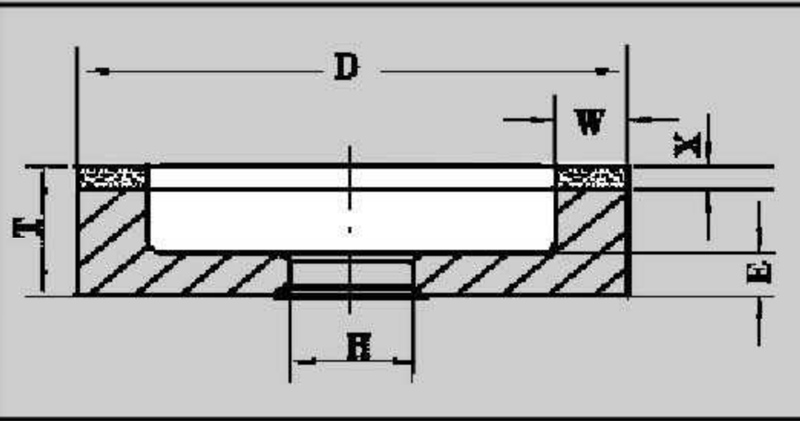

| OD | ID | THICKNESS | MESH SIZE |

| 80MM | 20MM | 15MM | D851 |

| D | T | H | W | X |

| 50 | 10-20 | 10 | 10-15 | 2/3/4/5/6 |

| 75 | 10-25 | 10,20 | 10-15 | 2/3/4/5/6 |

| 100 | 15-30 | 20 | 10-15 | 2/3/4/5/6 |

| 125 | 15-35 | 32 | 10-15 | 2/3/4/5/6 |

| 150 | 15-35 | 10-15 | 2/3/4/5/6 | |

| 175 | 15-40 | 30 | 2/3/4/5/6 | |

| 200 | 20-55 | 30 | 2/3/4/5/6 | |

| 250 | 20-55 | 2/3/4/5/6 | ||

| 300 | 25-60 | 127 | 30 | 2/3/4/5/6 |

| 350 | 33-60 | 35 | 2/3/4/5/6 |

1. High hardness and wear resistance

Diamond is used as the abrasive, which has extremely high hardness and wear resistance, and can easily meet the grinding needs of various hard materials.

2. Metal bonding agent

By using metal bonding agents to firmly bond diamond abrasive grains together, the strength and stability of the grinding wheel are improved, and the service life is extended.

3. Customized design

can be customized according to customer needs, including size, granularity, shape, etc., to meet the requirements of different processing scenarios and workpieces.

4. Efficient Processing

Suitable for grinding superhard materials such as PCD (Polycrystalline Diamond) and PCBN (Polycrystalline Cubic Boron Nitride), it has the characteristics of high processing efficiency and good surface quality.

5. Wide applicability

Not only suitable for metal processing, but also for processing hard and brittle materials such as ceramics, stone, glass, etc., with a wide range of application fields.

1A1 OD350MM Metal Bond Diamond Grinding Wheel is a type of grinding wheel that uses metal binders (such as bronze, nickel, etc.) to firmly bond diamond abrasive grains together.

Metal bond diamond grinding wheels play an important role in precision machining of ceramic materials due to their high strength, high wear resistance, and good thermal conductivity.

Metal Bond Diamond Grinding Pins are a type of diamond tool with excellent grinding performance and durability, widely used in precision and ultra precision machining of various hard and brittle materials.

If you need our products please write down any questions, we will reply as soon as possible.