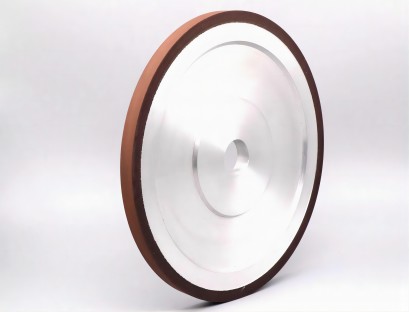

This type of Jincheng grinding wheel can be applied to various grinding processes such as outer and inner circles, flat surfaces, slotting, chamfering, etc., including hard alloys, diamond composite sheets, precision ceramics, mold steel, bearing steel, and other materials.

1A1 Resin Bond Diamond Grinding Wheels are widely used in the following fields:

1. Mechanical processing: Used for cutting and grinding various hard metal materials, such as bearing steel, mold steel, etc.

2. Optical processing: Used for rough grinding, fine grinding, and polishing of optical glass.

3. Gemstone processing: Used for the cutting, grinding, and polishing processes of gemstones.

4. Ceramic processing: Suitable for grinding and polishing various ceramic materials.

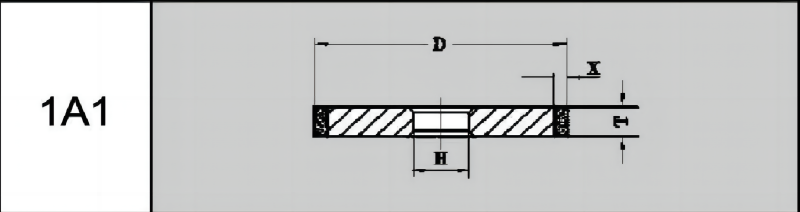

Unit:mm

| D | T | H | X |

| 50 | 5-20 | 20 | 3、5 |

| 60 | 5-20 | 20 | 3、5 |

| 70 | 5-20 | 20 | 5、10 |

| 75 | 5-20 | 20 | 5、10 |

| 80 | 5-20 | 20 | 5、10 |

| 100 | 5-50 | 20 | 5、10 |

| 125 | 5-50 | 20、32 | 5、10 |

| 150 | 5-50 | 32 | 5、10 |

| 175 | 5-30 | 32 | 5、10 |

| 200 | 10-30 | 32、75 | 5、10 |

| 250 | 10-40 | 75 | 5、10 |

| 300 | 10-40 | 75、127 | 5、10 |

| 350 | 10-40 | 127、203 | 5、10 |

| 400 | 15-50 | 127、203 | 5、10 |

| 500 | 20-50 | 305 | 5、10 |

| 600 | 20-30 | 305 | 10 |

1. High hardness and wear resistance

Diamond, as an abrasive, has extremely high hardness and wear resistance, and can effectively cut various hard materials.

Resin binders can firmly hold diamond abrasive grains, ensuring that they are not easily detached during the grinding process, thereby extending their service life.

2. Excellent cutting performance

Resin bonded diamond grinding wheels perform well in the cutting process, achieving efficient and precise grinding processing.

Its sharp cutting edge can reduce cutting force and cutting heat, lower the surface roughness of the workpiece, and improve machining quality.

3. Wide range of applications

1A1 Resin Bond Diamond Grinding Wheels are suitable for grinding various materials, including but not limited to metals, ceramics, glass, gemstones, etc.

Especially suitable for processing materials with high hardness and brittleness, such as hard alloys, optical glass, etc.

4. Easy to control and operate

Resin bonded diamond grinding wheels have good self sharpening properties during the grinding process, which can maintain the sharpness of the cutting edge and reduce the frequency of manual adjustment.

Meanwhile, its lower friction coefficient and good thermal conductivity help reduce cutting heat and cutting force, improving the stability and safety of machining.

5. For the end users, these grinding wheels can not only save clients production costs, but also Improve working effiency.

6. JINCHENG can not only make according to client drawing size, but also according to client special grinding situation,such as the hardness and shape of the ceramic grinding wheel required by the end user.Then clients will make sure that JINCHENG formulation is really suitable for end users.

7. The regular standard size is available in JINCHENG stock, when you need them, we can send them to you within a couple of days.

Jincheng 6A2 resin bond diamond grinding wheels are specifically designed for grinding glass and other hard materials. These wheels utilize a resin bond that provides a balance between cutting efficiency and surface finish quality.

9A1 Resin Bond Parallel Grinding Wheels is a parallel grinding wheel product that uses resin as a bonding agent.

14A1 Resin Bond Diamond Grinding Wheels can be applied to the machining of materials such as hard alloys, precision ceramics, high-speed steel, mold steel, bearing steel, etc., including cylindrical grinding, flat grinding, and blade grinding.

If you need our products please write down any questions, we will reply as soon as possible.